Production Equipment

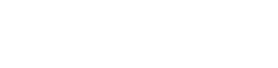

CNC Automatic Cutting Machine

KYUN JUN SYNTEC HB8BK

- Simple program to reduce setup lead times for rapid operation

- Quantity/length calculation function

- Full automation for unmanned operation

- High capacity feed bin

- Grinding wheel outer diameter wear automatic compensation function

- Rod filtering capability makes material supply smooth.

- Tolerance on length is within ±0.05mm

CNC Cylindrical Autoloading Grinder

JS-100CNC-P2-2D

- Fully automated in and out system

- Three grinding wheels can be used for finishing and rough machining

- Tool Precision V BLOCK centering mechanism ensures precise concentricity requirements

- Grinding wheel wear automatic correction

- One clamping can grind up to 8 complex shapes

- Precision grinding wheel spindle and high rigidity workpiece spindle

CNC Tool and Cutter Grinder

ANCA RX7

A unique mechanical concept and axes configuration provides high machine rigidity, which is required for grinding from solid, but at the same time ensures easy operator access and high-level ergonomics.

The direct-drive bi-directional spindle allows mounting of two wheel packs giving complete unrestricted access to the work piece.

With low power of 19 kW the RX7 offers very high performance output for a CNC tool grinder in this category. The mechanical design features of the RX7 are further complemented by the ANCA software. ANCA offers application software allows easy customization to produce special programs for a diverse range of non-standard applications.

Five-axis Tool Grinder

ANCA MX5 LINEAR

- The MX5 Linear uses ANCA LinX Linear Motors for axis motion (X & Y axis)

- 26 kW (35 HP) peak spindle power

- Linear scales as standard

- Compact machine with strength, power and versatility

- RoboMate or FastLoad-MX automatic tool loading options

- 2-station wheel pack with max. of 4 wheels each

- Includes integrated wheel dresser

- The MX5 Linear is ideal for grinding tools up to 16 mm diameter

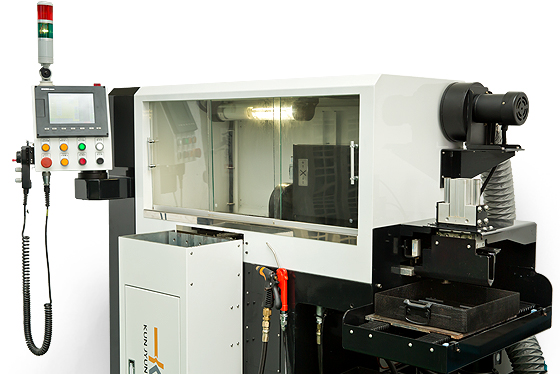

Five-axis Tool Grinder

ANCA TX7+

- Suitable for heavy-duty manufacturing and reconditioning precision cutting and drilling tools, plus component manufacture

- Automatic wheel changer enables up to 8 grinding wheels to be used in one set-up

- Wide variety of workholding and support tooling to meet individual needs

- RoboMate automation for unmanned operation

- 37 kW (49 HP) peak spindle power

- Integrated dresser roll on the headstock

Detection Equipment

Image Type Tool Inspection Device

- Fixed magnification and fixed focal length.

- It can generate CNC codes and can be online with CNC machine for tool length compensation.

- Applicable for tool management.

- The use of surface light allows for inspecting tool surface and contour.

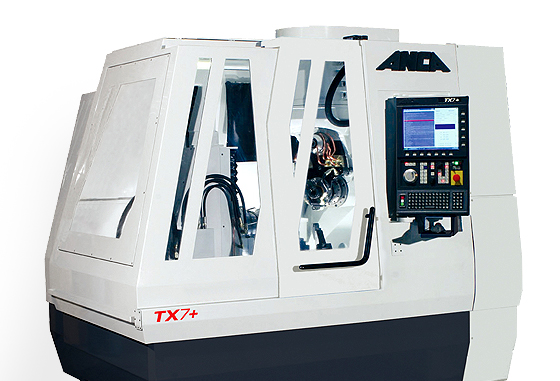

Tool Measuring Equipment

Janpo uses Zoller measuring instrument from Germany to monitor the measuring process with Pilot NC system software, and uses Delta measuring program to determine whether the end mills are conformed to preset standards or not. In addition, the central height of the measuring module of Zoller allows the inspector to learn the damage and wear conditions of the end mills through a special lighting and image processing system, and handle the products timely and rapidly. This enables Janpo to have maximum control of the quality management of our products, thereby offering flawless products to our clients.

Tool observation instrument

- Fixed magnification and focal length.

- Applicable for tool management.

- The use of surface light allows for inspecting tool surface and profile.